Papermaking

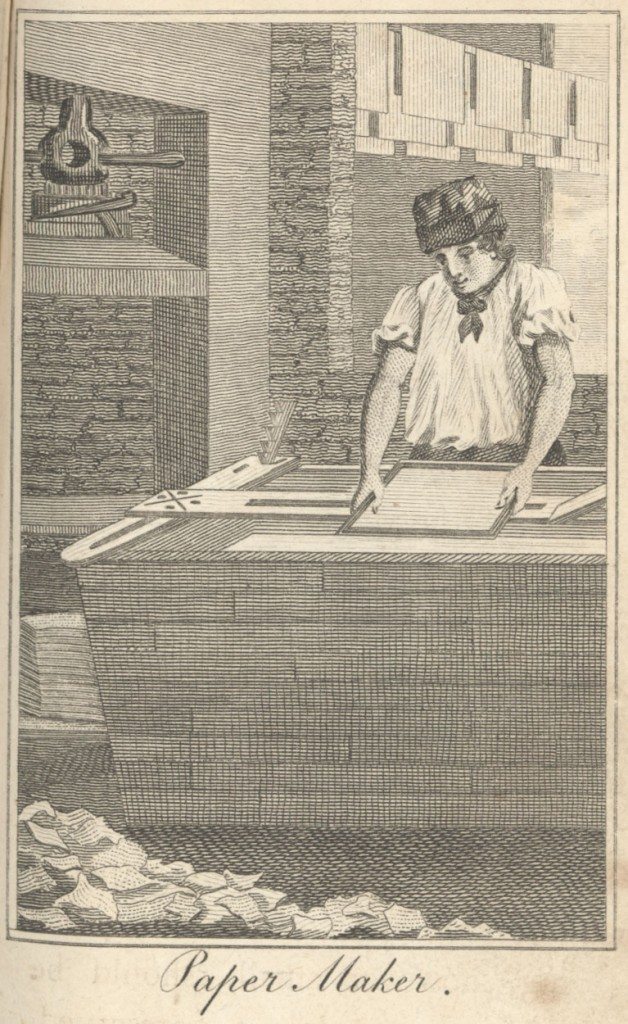

Image: Paper Maker, from The Book of Trades or Library of Useful Arts, part III, third edition (London Tabart and Co, 1806). Paper was made from linen rags which were cleaned with water and pulverised so that the cloth was turned into a thin pulp. In the copper-plate engraving, the pulp is kept warm in a wooden tub. The workman or vat-man uses a mould which is composed of wires set into a wooden frame. The workman holds the frame in both hands and plunges it horizontally into the tub. The mould is removed and the water runs away leaving a thin coat of pulp. This forms the sheet of paper. A second worker, the coucher, takes the mould and places the sheet of paper on a felt or woollen cloth. Alternative sheets of cloth and paper are laid on top of each other to form quires. These are pressed. They are removed from the cloth and pressed again. After several pressings the sheets are hung on lines to dry. The paper is then sized to allow it to take ink. The size contains shreds and parings from tanners, curriers and parchment makers together with alum, a chemical. The paper is dipped into the vessel, pressed again and dried. . When it is pressed, selected, examined, folded and made into reams, it is ready for printing.

Image from: Science Technology and Management, Birmingham Central Library

From the days when man first developed language and pictorial communication a means of display for this artistic expression had to be found. Cave-drawings, hieroglyphics and other picture-based scripts were transferred from immovable walls to objects which could easily be transported from place to place. These included animal hides, barks of certain trees, interlaced papyrus which was hammered into sheets and silk weavings which could be rolled or folded. Social records were taken down some of which have outlived the dynasties they recorded.

An old rhyme goes:

Rags make paper

Paper makes money

Money makes banks

Banks make beggars

Beggars make rags.

When paper was invented it revolutionised the whole communications industry being flexible and less expensive than other writing materials. Made mostly from rags and ropes it was an early example of recycling and provided for its users a smoother surface on which to write or paint. Ts’ai Lun was the first-known papermaker and he is credited with its invention. He was a eunuch at the imperial court of Ho-ti and in 105 A.D. made paper for his emperor. Honoured for his ingenuity the papermaking process was kept secret from the rest of the world for four centuries. The technique spread east to Japan and then west via the Silk Road to Samarkand when in 751 A.D, Chinese papermakers were captured at the battle of Talas. Fifty years later paper was being manufactured in the enlightened city of Baghdad making the reproduction of Islamic texts onto paper possible. From there concentration of the craft moved slowly northwards to Spain in the 12th century and then to Italy, France and Germany, finding its way eventually to England.

Papermaking in England was introduced independently by John Tate in 1495 in Hertfordshire. This is later than Shakespeare would have us believe, unless he knew something we do not. In Henry VI he writes: “…thou hast caused printing to be used, and, contrary to the king, his crown, and dignity, thou has built a paper mill.” 1

Kent, the garden of England, was the centre of papermaking in Britain for many centuries, following its introduction from the continent. Papermakers from Europe were encouraged to come over the channel and further spread the art.

1 Henry VI, Part II, Act IV, Scene VII

« Previous in this sectionNext in this section »Continue browsing this section

Papermaking, Printing and Associated Trades in the West Midlands during the 18th and Early 19th Centuries

Papermaking, Printing and Associated Trades in the West Midlands during the 18th and Early 19th Centuries

Papermaking

Papermaking

Printing

Printing

Papermaking in the West Midlands

Papermaking in the West Midlands

Baskerville and Alternative Technology

Baskerville and Alternative Technology

Baskerville and Printing

Baskerville and Printing