Charcoal and its Uses

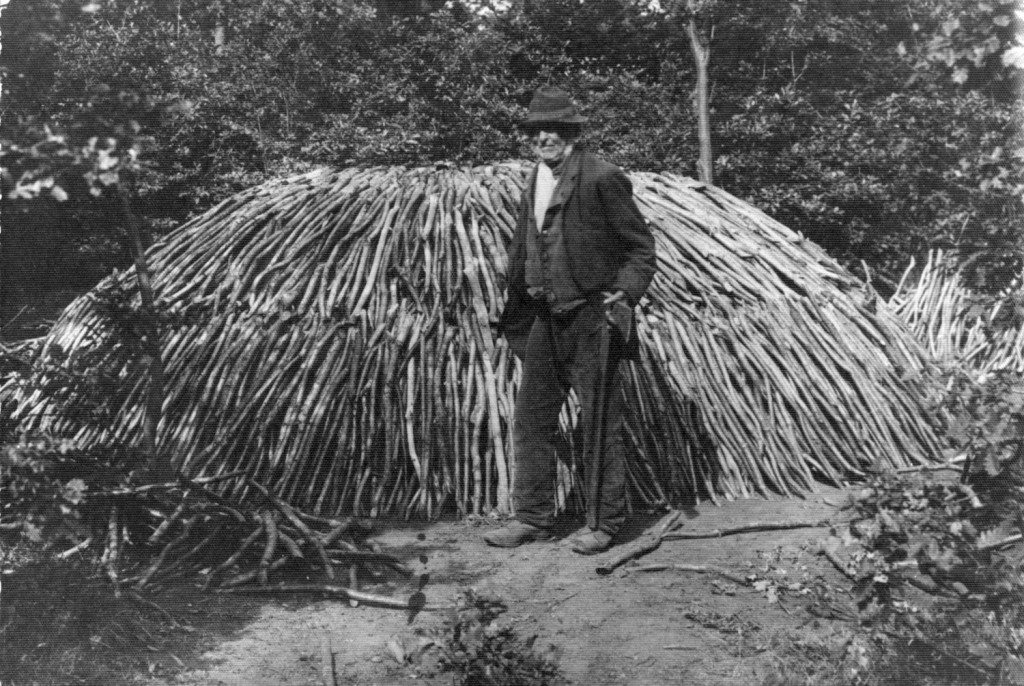

Image: Charcoal burning in the Wyre Forest. The photograph shows a completed clamp ready for firing in the Wyre Forest with a charcoal burner standing in front. [Image from: Bewdley Museum from an image in the Stone Collection, Birmingham Central Library (late 19th century)]

1. Charcoal and its Uses

Charcoal has been used as a fuel for thousands of years. Its history was linked with the smelting of metals for which it was an ideal fuel because it produces an intense smokeless heat. Charcoal is made by heating wood in a furnace where air is restricted to reduce the rate of burning. The aim is to remove unwanted elements, such as water, creosote and tar and to leave pure black carbon. This can be used as a fuel without imparting impurities into the products which are being smelted.

In the Wyre Forest charcoal was produced from at least the 12th or 13th centuries when there was demand for the fuel from iron workers in Dudley and Halesowen and salt workers in Droitwich. Its use expanded heavily in the 16th and 17th centuries, and remained high in the 18th and 19th centuries. In his General View of the Agriculture of the County of Worcester in 1813, W. Pitt implied that the industry was a significant part of the county’s economy. He noted that great quantities of wood “are burnt into charcoal for the use of the ironworks upon the Stour, and Staffordshire; but some is occasionally used for fuel.”

Wyre Forest charcoal, in fact, was used for several purposes:

• Glass blowing in Stourbridge and Bromsgrove.

• Drying hops in the Teme Valley for brewing.

• Boiling brine to produce salt in the Droitwich area.

• As an ingredient in gunpowder.

• Preserving food.

• Brass making in Bewdley.

• Iron smelting, not only for the Black Country industry, but also for local furnaces in Mawley, Cleobury Mortimer and Furnace Mill on Dowles Brook near Bewdley.

Many types of wood were used for charcoal burning, but their properties were different:

• Holly and beech produced a “coal” that was heavy, compact and strong, preferred by ironmasters and glassblowers.

• Oak produced a similar quality, but it tended to flake.

• Willow and alder was light and soft and produced more suitable charcoal for gunpowder.

• Ash, elm and beech produced a less dense “coal” and coniferous trees produced a light and friable product which was more suitable for domestic uses.

By the 17th century, charcoal burning had depleted much of Britain’s forested areas. In order to preserve a disappearing resource, coppicing was introduced and trees were harvested in rotation cycles lasting from 7 to 25 years, a practice which continued until the early 20th century.

« Previous in this sectionNext in this section »Continue browsing this section

Charcoal Burning in the Wyre Forest

Charcoal Burning in the Wyre Forest

Charcoal and its Uses

Charcoal and its Uses

Work and Labour

Work and Labour

Charcoal Burning

Charcoal Burning

Charcoal Burning

Charcoal Burning

Charcoal Burning

Charcoal Burning

Charcoal Burning

Charcoal Burning

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal Burning Tools

Charcoal burning: Retorts

Charcoal burning: Retorts

Charcoal Burning: Retorts

Charcoal Burning: Retorts

The Decline of Charcoal Burning

The Decline of Charcoal Burning