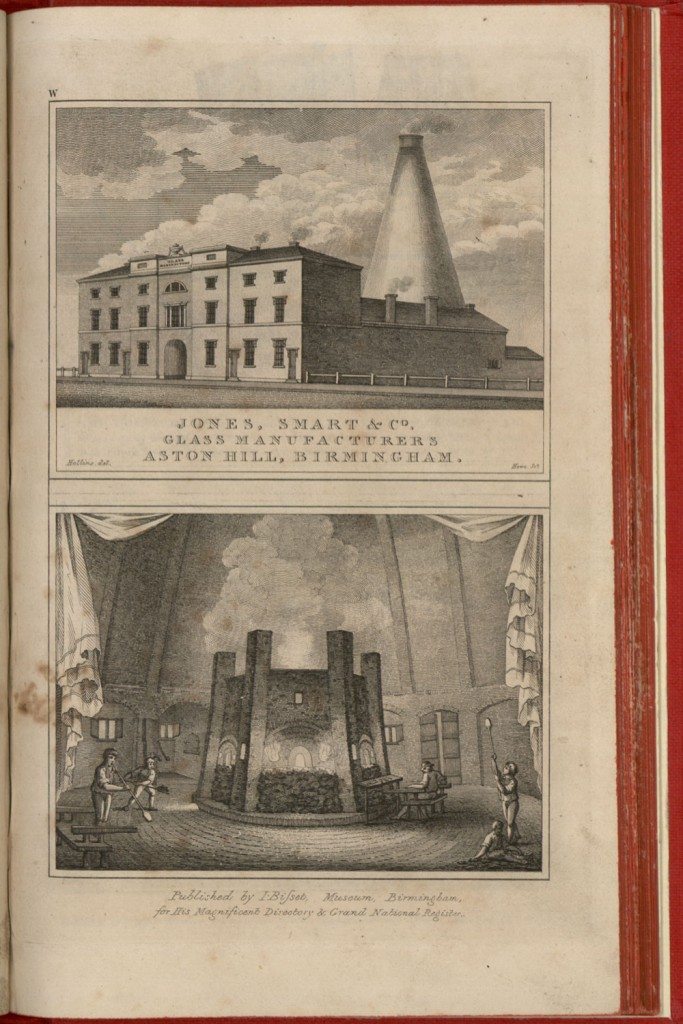

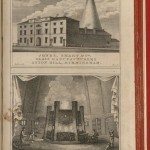

Exterior and Interior View of Jones, Smart and Company’s Glass Manufacturers, Aston Hill, Birmingham

One of several glass houses in Birmingham. The exterior view of Jones’ and Smart’s Glass House is dominated by the glasshouse cone, a huge brick structure, from which smoke emerges. The cone served as a giant chimney, creating an updraught for the furnace. The interior view of the cone shows the furnace and glassmakers at work. Glass was melted inside clay pots and the glassblowers inserted their irons into the furnace to withdraw the molten glass. A boy on the left, called a teaser, feeds coals into the furnace. Next to him the servitor is blowing glass to create the bowl of a wineglass. On the right, the footmaker roughly forms a lump of molten glass on his iron. Close to the furnace, the senior workman, the gaffer, is seated at the glassmaker’s chair. He shapes small lumps of glass brought to him by the footmaker to create the stem and foot of the wineglass. The gaffer also connected the stem and bowl. The glass had to be kept at a high temperature to enable it to be soft and workable and would therefore have to be reheated. When finished it was taken to an annealing chamber. This was a long tunnel where heat was maintained at different temperatures through which glass was drawn so that it could be cooled very slowly. The glass could then be engraved and cut.

« Previous in this sectionNext in this section »Continue browsing this section

A Catalogue of Commerce and Art: Bisset’s Magnificent Guide for Birmingham, 1808

A Catalogue of Commerce and Art: Bisset’s Magnificent Guide for Birmingham, 1808

Frontispiece to Bisset’s Magnificent Directory

Frontispiece to Bisset’s Magnificent Directory

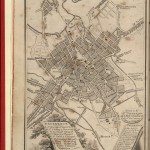

Plan of Birmingham, drawn by J. Sherrif of Oldswinford, late of the Crescent Birmingham

Plan of Birmingham, drawn by J. Sherrif of Oldswinford, late of the Crescent Birmingham

Birmingham Fire Office

Birmingham Fire Office

Bankers and Public Companies in Birmingham

Bankers and Public Companies in Birmingham

Physicians, Surgeons, Apothecaries and Chemists in Birmingham

Physicians, Surgeons, Apothecaries and Chemists in Birmingham

Attorneys at Law in Birmingham

Attorneys at Law in Birmingham

Sword, Gun and Pistol Manufacturers in Birmingham

Sword, Gun and Pistol Manufacturers in Birmingham

Mercers, Linen Drapers, Haberdashers, Hosiers and Lacemen in Birmingham

Mercers, Linen Drapers, Haberdashers, Hosiers and Lacemen in Birmingham

J Taylor, Gold and Silversmith, Jeweller, Tortoiseshell and Ivory Box and Toy Manufacturer, Birmingham

J Taylor, Gold and Silversmith, Jeweller, Tortoiseshell and Ivory Box and Toy Manufacturer, Birmingham

Cabinet Makers, Upholsterers, Gun Makers and Saddlers in Birmingham

Cabinet Makers, Upholsterers, Gun Makers and Saddlers in Birmingham

Birmingham in Miniature or Richard’s Magazine for the Manufacturers of Birmingham and its Vicinity

Birmingham in Miniature or Richard’s Magazine for the Manufacturers of Birmingham and its Vicinity

Bankers in Birmingham and Businessmen adjacent to Birmingham

Bankers in Birmingham and Businessmen adjacent to Birmingham

Merchants in Birmingham

Merchants in Birmingham

Miscellaneous Businesses in New Street, Birmingham

Miscellaneous Businesses in New Street, Birmingham

Miscellaneous Businesses in High Street, Birmingham

Miscellaneous Businesses in High Street, Birmingham

Gun Makers in Birmingham

Gun Makers in Birmingham

Inns, Hotels and Taverns and Swinney’s Type Foundry in Birmingham

Inns, Hotels and Taverns and Swinney’s Type Foundry in Birmingham

Factors or Commercial Agents in Birmingham with a view of the Crescent and Wharf

Factors or Commercial Agents in Birmingham with a view of the Crescent and Wharf

Miscellaneous Professions and Businesses in Birmingham with a View of St Philip’s Church

Miscellaneous Professions and Businesses in Birmingham with a View of St Philip’s Church

Miscellaneous Professions and Businesses in Birmingham with Emblems of their Trade

Miscellaneous Professions and Businesses in Birmingham with Emblems of their Trade

Henry Clay, Japanner, and Artists in Birmingham

Henry Clay, Japanner, and Artists in Birmingham

Sword Makers in Birmingham

Sword Makers in Birmingham

Brass Founders with a view of the Brass House in Broad Street, Birmingham and Miscellaneous Businesses

Brass Founders with a view of the Brass House in Broad Street, Birmingham and Miscellaneous Businesses

Toy Makers in Birmingham with a View of the Navigation Offices

Toy Makers in Birmingham with a View of the Navigation Offices

Miscellaneous Professions and Businesses in Birmingham with a View of St Paul’s Chapel

Miscellaneous Professions and Businesses in Birmingham with a View of St Paul’s Chapel

Japanners in Birmingham and a View of the Park Glass House

Japanners in Birmingham and a View of the Park Glass House

Cards of different Professions and Businesses in Birmingham

Cards of different Professions and Businesses in Birmingham

Miscellaneous Businesses in Birmingham with a View of the Town from the Warwick Canal

Miscellaneous Businesses in Birmingham with a View of the Town from the Warwick Canal

Button Makers in Birmingham

Button Makers in Birmingham

Miscellaneous Professions and Businesses in Deritend near Birmingham

Miscellaneous Professions and Businesses in Deritend near Birmingham

View of Matthew Boulton’s Soho Manufactory and Royal Mint Offices in Handsworth near Birmingham

View of Matthew Boulton’s Soho Manufactory and Royal Mint Offices in Handsworth near Birmingham

View of the Eagle Iron Foundry and Mr. Whitmore’s Engineering Works in Birmingham

View of the Eagle Iron Foundry and Mr. Whitmore’s Engineering Works in Birmingham

View of Lloyd’s, New Hotel and Hen and Chickens Inn, New Street, Birmingham

View of Lloyd’s, New Hotel and Hen and Chickens Inn, New Street, Birmingham

Exterior and Interior View of Jones, Smart and Company’s Glass Manufacturers, Aston Hill, Birmingham

Exterior and Interior View of Jones, Smart and Company’s Glass Manufacturers, Aston Hill, Birmingham

Thomason’s Button and Toy Manufactory, Church Street, Birmingham

Thomason’s Button and Toy Manufactory, Church Street, Birmingham

View of the Westminster Life and British Fire Insurance Offices, Strand, London, with a List of the Directors. J. Gottwaltz, Birmingham Agent

View of the Westminster Life and British Fire Insurance Offices, Strand, London, with a List of the Directors. J. Gottwaltz, Birmingham Agent

The Phoenix Fire Office, Lombard Street and Charing Cross, London, with a List of the Directors. J. Farror, Birmingham Agent.

The Phoenix Fire Office, Lombard Street and Charing Cross, London, with a List of the Directors. J. Farror, Birmingham Agent.

Two Manufacturers, a School, an Engineer and an Inn near Birmingham

Two Manufacturers, a School, an Engineer and an Inn near Birmingham

Blair and Sutherlands, Gun Makers, Brook Street and Harper’s Hill, Birmingham

Blair and Sutherlands, Gun Makers, Brook Street and Harper’s Hill, Birmingham

Button Makers and other Businesses of Birmingham

Button Makers and other Businesses of Birmingham

View of Birmingham from Aston Wharf with the Names of various Businesses

View of Birmingham from Aston Wharf with the Names of various Businesses

Miscellaneous Metal Manufacturers and other Businesses in Birmingham

Miscellaneous Metal Manufacturers and other Businesses in Birmingham

Toy Maker and Japanners in Birmingham

Toy Maker and Japanners in Birmingham

Surveyor, Sutton Coldfield and Coach Spring Manufacturers, Birmingham

Surveyor, Sutton Coldfield and Coach Spring Manufacturers, Birmingham

A Bookseller and list of Appraisers and Auctioneers in Birmingham

A Bookseller and list of Appraisers and Auctioneers in Birmingham

Merchants and Factors in Birmingham

Merchants and Factors in Birmingham

Hepinstall and Parker’s File Manufactory, Ann Street, Birmingham and Walsall, Staffordshire

Hepinstall and Parker’s File Manufactory, Ann Street, Birmingham and Walsall, Staffordshire

Miscellaneous Traders, Professions and Manufacturers in Birmingham

Miscellaneous Traders, Professions and Manufacturers in Birmingham

Trade Cards for various Businesses in Birmingham

Trade Cards for various Businesses in Birmingham

View of Warstone Brewery, Warstone Lane, Birmingham, belonging to Alex Forrest and Sons

View of Warstone Brewery, Warstone Lane, Birmingham, belonging to Alex Forrest and Sons

Various Toy Makers and Jewellers in Birmingham

Various Toy Makers and Jewellers in Birmingham

Thomas Robinson, Chemist, and Roberts, Jeffery and Co, Button and Toy Manufacturers, Snow Hill, Birmingham

Thomas Robinson, Chemist, and Roberts, Jeffery and Co, Button and Toy Manufacturers, Snow Hill, Birmingham