Flint Glass

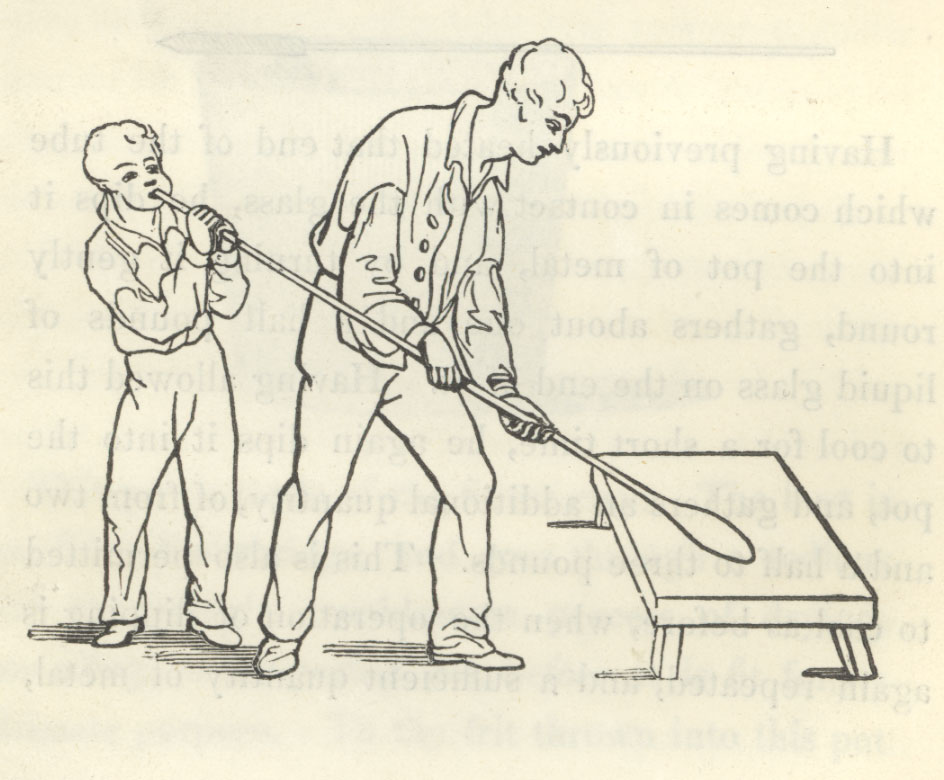

Image: Glassmaking. Rolling a tube of red-hot glass to reach the desired shape. The boy or gamin continued to blow through the tube. William Cooper, Crown Glass Cutter & Glazier’s Manual (1835).

Image from: Science, Technology and Management, Birmingham Central Library

Flint glass production was similar to the making of Crown glass. A ball of “metal” was placed on an iron rod, which the workman whirled around his head before rolling it on an iron slab. The “metal” was then rendered hollow by blowing down the tube. The blower then sat on a chair with arms sloping downwards and rolled the tube rapidly on the arms of the chair. A boy or “gamin” continued to blow down the tube at regular intervals until the desired dimensions were attained. Great care was needed to regulate the thickness of the glass and the workman constantly measured the glass with his compass and scale. Flint glass was of a high transparency and was often used to make highly ornate pieces of glassware. These were made principally by blowing molten glass into a hollow and then teasing the shape with hand tools or moulds to produce the desired article.

« Previous in this sectionNext in this section »Continue browsing this section

The Infinite Uses of Glass: Chance Brothers, Glassmakers of Smethwick

The Infinite Uses of Glass: Chance Brothers, Glassmakers of Smethwick

Chance Brothers and Company

Chance Brothers and Company

The Arrival of Expert Workers

The Arrival of Expert Workers

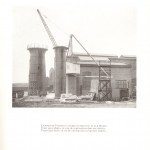

The Chemical Works

The Chemical Works

Types of Glass

Types of Glass

Crown Glass

Crown Glass

Plate or Sheet Glass

Plate or Sheet Glass

Flint Glass

Flint Glass

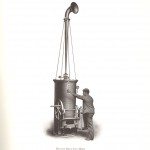

New Technology

New Technology

Glazing the Crystal Palace

Glazing the Crystal Palace

Glazing the Crystal Palace

Glazing the Crystal Palace

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Company Philanthropic Activity

Company Philanthropic Activity

Relations between Workers and the Company

Relations between Workers and the Company

French and Belgian Workers

French and Belgian Workers

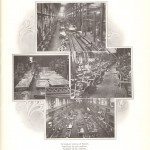

Description of the Glassworks

Description of the Glassworks

Description of the Glassworks

Description of the Glassworks