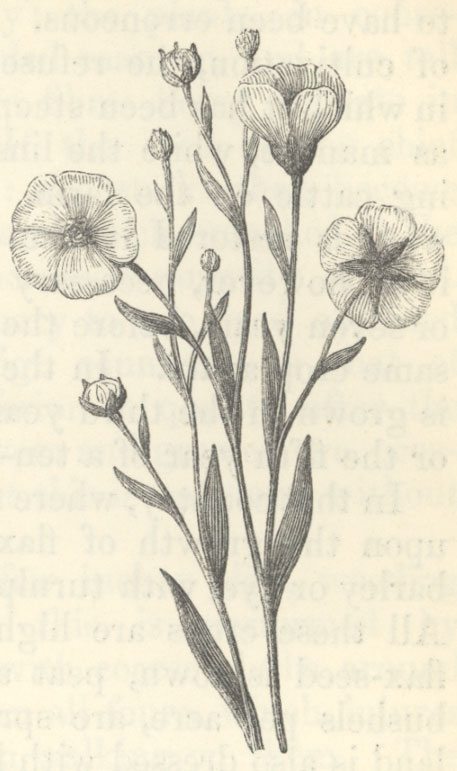

Growing and Preparing Flax

Image: The flax plant. The Useful Arts and Manufactures of Great Britain, vol. 1 (London, SPCK, 1846?).

Image from: Science, Technology and Management, Birmingham Central Library

Linen cloth is produced from the fibres of a plant, flax. Flax spinning and the weaving of woollen cloth developed as an industry in the Middle East in ancient times. Flax was grown across the world and by the late eighteenth century its cultivation was widespread in the Netherlands, France, Russia and Prussia. After harvesting, the crop was rippled where flax was drawn through the teeth of a comb to remove the bolls or seed-heads from the stalks. The bolls could then be used for cattle feed.

The next stage was steeping or retting to enable the fibrous bark to be separated from the woody portion of the stem. The stalks were soaked in water and after eight to twelve days, the flax was removed and dried.

After these preparatory activities which were performed where the flax was grown, the raw flax was processed prior to spinning. By the late eighteenth century, flax mills were conducting a lot of the work, often at some distance from the place of origin of the crop itself. Examples included John Marshall’s factories in Leeds and the Ditherington Mill of Marshall, Benyon and Bage.

« Previous in this sectionNext in this section »Continue browsing this section

Charles Bage, the Flax Industry and Shrewsbury’s Iron-Framed Mills

Charles Bage, the Flax Industry and Shrewsbury’s Iron-Framed Mills

Shrewsbury’s Industrial Context

Shrewsbury’s Industrial Context

The Location of Ditherington Mill

The Location of Ditherington Mill

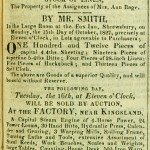

Bill for the supply of liquor from Charles Bage to Lord Clive 1792

Bill for the supply of liquor from Charles Bage to Lord Clive 1792

Charles Bage and Iron Construction

Charles Bage and Iron Construction

Charles Bage: Business and Local Affairs

Charles Bage: Business and Local Affairs

Thomas and Benjamin Benyon

Thomas and Benjamin Benyon

John Marshall

John Marshall

Growing and Preparing Flax

Growing and Preparing Flax

Processing and Spinning Flax

Processing and Spinning Flax

Ditherington Flax Mill

Ditherington Flax Mill

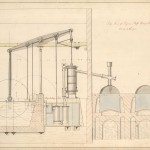

Ditherington Mill: Steam Power

Ditherington Mill: Steam Power

Ditherington Mill: Steam Power

Ditherington Mill: Steam Power

Castlefields Mill: Origins

Castlefields Mill: Origins

Castlefields Mill: Steam Power

Castlefields Mill: Steam Power

Castlefields Mill: the Flax Warehouse

Castlefields Mill: the Flax Warehouse

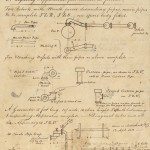

Castlefields Mill: Gas Lighting

Castlefields Mill: Gas Lighting

Castlefields Mill: Gas Lighting

Castlefields Mill: Gas Lighting

Castlefields Mill: Sale and Demolition

Castlefields Mill: Sale and Demolition

Kingsland Mill

Kingsland Mill