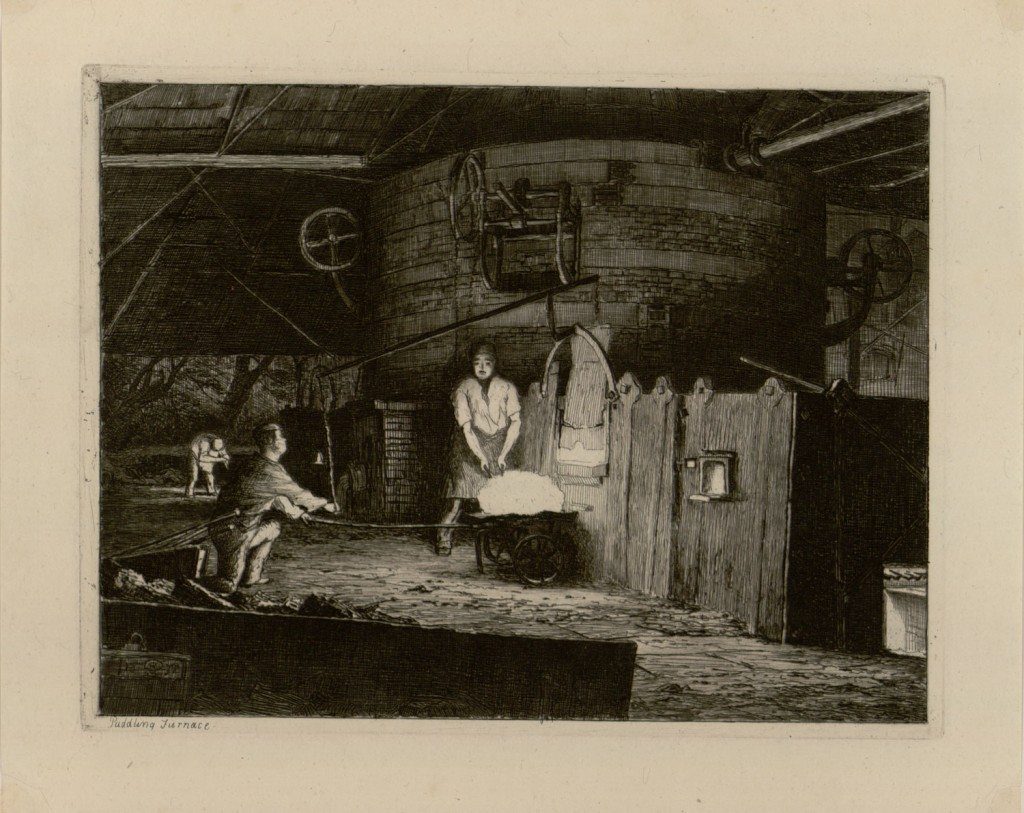

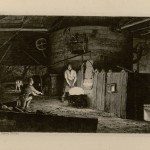

The Puddling-Furnace

In order to eliminate from the pig-iron the carbon and impurities with which, as it runs from the blast-furnace, it is charged, it is subjected to the process known as ‘puddling’. The pigs of metal are melted in an air-furnace, and the fused mass, of about the consistency of ‘white-wash’, is violently stirred by means of long iron tools thrust through a small opening in the furnace-door. After a long time the iron begins to thicken and separate itself, when it is said to be ‘coming to nature,’ and it becomes the business of the puddler to work it into large balls for the after processes of consolidation and rolling. When the ball is ready for extraction the puddler’s assistant raises the door of the furnace, while the puddler, seizing the ball with long pincers, works it through the opening on to a small iron carriage, termed in South Staffordshire the ‘bogie,’ and it is at once wheeled away.

« Previous in this sectionContinue browsing this section

The Industrial Landscape of the Black Country

The Industrial Landscape of the Black Country

Geology

Geology

Industrial Origins

Industrial Origins

Impressions

Impressions

Illustrations of the Black Country Landscape

Illustrations of the Black Country Landscape

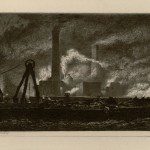

Blast Furnaces, Cradley

Blast Furnaces, Cradley

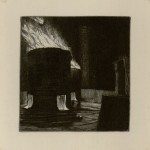

The Tunnel-Head

The Tunnel-Head

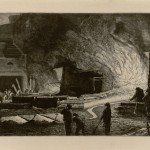

Tapping the Blast-Furnace

Tapping the Blast-Furnace

The Puddling-Furnace

The Puddling-Furnace