The Staffordshire Potteries Directory: An Account of the Pottery Manufacture

Published in 1802, this Directory is one of the first written accounts of the pottery towns, Tunstall, Burslem, Etruria, Hanley and Fenton (Lower Lane) and Stoke-upon-Trent. Later in the 19th century they joined together to form the borough of Stoke-on-Trent. Printed when the area had just taken off as a major industrial centre, the Directory provides a snapshot of industrial, commercial and religious life in the Potteries as it became Britain’s, and possibly the world’s most important centre for the production of ceramics. The author of the Directory draws attention to the district’s rapid growth and buoyant labour market:

About a mile from the borders of Cheshire, the Staffordshire Potteries commence, at a small village called Green-lane; from whence, to the other extremity of the Pottery at Lane-end is about ten-miles; a considerable part of which, by joining together, strikes the traveller as but one town, although under different names. The manufacturing of Earthen-wares, is the general and nearly sole business, of this extensive and very populous quarter; and from the great increase of inhabitants and houses, in the last 30 years, in all probability, the various towns and villages…will ere long be so intermixed with buildings, as to form only one town and one name. At a little distance, they are all of them already ranked under the general name of The Pottery.

The Pottery may with propriety be styled “The Seat of Industry.” Whilst the strong and active are engaged in the more laborious and difficult branches of manufacture, children of five or six years, and decrepit old age, tottering on the brink of another world, find employ suitable to their strength and abilities.

(Directory, Pages 1-3 and 26)

The publication includes the following sections:

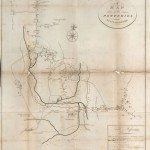

• A map of the Potteries with a key. It identifies the locations of the main earthenware manufactories, rivers, roads, canals and wharfs together with local places of worship. It provides a plan of what was still a semi-rural area stretching from Green Lane in the north to Newcastle and Handford in the south, and from Woolstanton in the west to Lane End in the East.

• The History of the Staffordshire Potteries. This survey explores 18 different townships and villages, looking at the geography of manufacturing, the seats of principal residents, churches and chapels and occasional insights into education, social welfare provision and patterns of labour.

• An Account of the Pottery Manufacture. This is reproduced and transcribed for the website.

• Tables of distances, rates of freight etc., from the Rivers Trent to Mersey and on the Staffordshire, Worcestershire and Birmingham Canals.

• A directory containing an alphabetical list of the names and locations of “the Gentlemen, Tradesmen, shop-keepers etc.,” in the Staffordshire Potteries.

• Lists of stage wagons and stage and mail coaches passing through Newcastle-under-Lyme and the Potteries

The Account of the Pottery Manufacture is a record of the “rise, progress, and present state” of the industrial evolution of the area, looking at technological developments, types of ceramic ware and the specific achievements of the master potter, Josiah Wedgwood.

[28]

Account of the Pottery Manufacture

This part of the country, from the clays and coal mines which it abounds with, appears better adapted for a manufactury of earthen-wares, than perhaps for any other. The measures or strata, by which the beds of coal are divided, consist most commonly of clays of different kinds; some of which make both excellent fire-brick for building the potters’ kilns and saggers,* or cases in which the ware is burnt. Finer clays, of

* Dr Aikin observes “this is a corruption of the German word schragers, which signifies cases of supporters;” – but we think it probable it may be a corruption of the English word safeguard.

[29]

various colours and textures, are likewise plentiful in many places, most of them near the surface of the earth; and of these, the bodies of the wares themselves were formerly manufactured. The coals being then also got near the surface, were plentiful and cheap. Dr Plot states them, so late as his time, at two-pence the horse load, which, at eight horse loads to a ton, (the common estimation) amounts only to sixteen-pence per ton. The land having chiefly a clay bottom, was unfavourable to the productions of husbandry; and its remoteness from the feats of commerce, contributed further to render labour cheap. All these circumstances considered together, with some others which will be mentioned

[30]

hereafter, may possibly afford the best answer to a question which has often been asked, why the Pottery was established in Staffordshire, preferable to any other place, and why it still continues to flourish there more than in any other part of the kingdom, or perhaps the world.

How long this kind of manufacture has subsisted here, is utterly unknown. It can be traced with certainty for at least two centuries back; and no document or tradition remains of its first introduction. Its principal seat seems to have been formerly the town of Burslem, and it was then called a Butter Pottery; that is, a manufactury of pots in which butter was kept; and we have seen it so denominated in a

[31]

very old map. As a proof of the antiquity of the manufacture in this neighbourhood, it may be proper to mention, that about seventy five years ago, below the foundation of a building then taken down, and supposed to have been not less than a hundred years old, the bottom of a potter’s kiln was discovered, with some of the saggers upon it, and pieces of the wares in them; and that about the same time a road which had long before been made across a field, being worn down into a hollow way, the hearth of a potter’s kiln was found to be cut through by this hollow part of the road; and it was not among the then existing, or then remembered Potteries, that these old works were discovered, but at a considerable

[32]

distance, in places where no tradition remained among the oldest inhabitants of the neighbouring villages that any Pot-works had ever been. It may be added, that pieces of ware, of the rudest workmanship, and without any glaze or varnish, are frequently met with in digging for the foundations of new erections.

Though the old remains are undoubtedly the productions of distant periods, they give little or no light into the successive improvements made in the art, nor indeed could any good purpose be answered by an enquiry of that kind; for though the manufacture has, within our memory, advanced with amazing rapidity to its present magnitude, it seems to have continued

[33]

for a long series of years almost uniformly rude and uninteresting. Even so late as the year 1686, when Dr. Plot published his history of the country, the quantity of goods manufactured was so inconsiderable, that “the principal sale of them,” the Dr. says, “was to poor crate-men, who carried them on their backs all over the country!” All the ware was then of the coarse yellow, red, black and mottled, made from the clays found in the neighbourhood, as already mentioned; the body of the ware being formed of the inferior kinds of clay, and afterwards painted or mottled with the finer coloured mixed with water, separately or blended together, much in the same manner that paper is marbled. The common

[34]

glaze was produced by lead ore, finely powdered and sprinkled on the pieces of ware before firing; sometimes with the addition of a little manganese, on account of the brown colour it communicates; and, when the potter wished “to show the utmost of his skill,” (to use Dr. Plot’s expression) in giving the ware a higher gloss than ordinary, he employed, instead of lead ore, calcined lead itself, but still sprinkled it on the pieces in the same rude manner.

The era of improvement commenced a few years after the publication of Plot’s work, by the introduction of a new species of glaze, produced by throwing into the kiln, when brought to its greatest heat, a

[35]

quantity of common salt, the fumes of which occasioned a superficial vitrification of the clay. How long this practice might have subsisted in other countries is unknown; but it was first brought hither about the year 1690, by two ingenious foreigners of the name of Elers, who established a small pot-work at Bradwall, near Burslem; and it is said that the inhabitants of Burslem flocked with astonishment to see the immense volumes of smoke which rose from the Dutchmen’s ovens, on casting in the salt; a circumstance which sufficiently shows the novelty of this practice in the Staffordshire Potteries. The same persons introduced likewise another species of ware, in imitation of the unglazed red China from the East; and the clays in this

[36]

country being suitable for the purpose, they succeeded wonderfully for a first attempt, insomuch that some of their tea-pots are said to have been sold so high as a guinea-a-piece; and some of the specimens which still remain in the country are very perfect in their kind, as well with respect to the texture and quality of the ware itself, as to the form and workmanship. – The foreigners, however, did not long continue in this situation; finding the manufacturers about them very inquisitive, and not choosing to have their procedures so narrowly inspected, they quitted Staffordshire, and set up a manufactury near London.

The establishment of the new glaze with salt was succeeded, in a short

[37]

time by a capital improvement in the body of the ware itself, which the tradition of the country attributes to the following incident:

One of the potters (Mr. Astbury,) in a journey to London, happened to have powdered flint recommended him by the hostler of his inn at Dunstable, for curing some disorder in one of his horse’s eyes; and for that purpose a flint stone was thrown into the fire to render it more easily pulverable. The potter, observing the flint to be changed by the fire to a pure white, was immediately struck with the idea that his ware might be improved by an addition of this material to the whitest clays he

[38]

could procure. Accordingly he sent home a quantity of the flint stones, which are plentiful among the chalk in that part of the country, and on trial of them, with tobacco pipe clay, the event proved fully answerable to his expectation. Thus originated the white stone ware, which soon supplanted the coloured ones, and continued for many years the staple branch of pottery.

Those who became first acquainted with the great improvement produced by the addition of flint, endeavouring as it is usual in such cases to keep the secret to themselves, had the flints pounded in mortars by manual labour, in cellars or private rooms; but the operation proved pernicious to many

[39]

of the workmen, the fine dust getting into the lungs, and producing dreadful coughs and consumptions, and these alarming complaints of the men may be presumed to have hastened the discovery of the source from which they had arisen. The secret becoming generally known, the consequent increase of demand for the flint powder, occasioned trials to be made of mills, of various constructions, for stamping and grinding it, and the ill effect of the dust, which could not be entirely guarded against when the stones were either pounded or ground dry, pointed out an addition of water in the grinding. This method being found effectual as well as safe, it still continued; the ground flint comes from

[40]

the mill in a liquid state about the consistence of cream; and the tobacco pipe clay being mixed up with water to the same consistence, the two liquids are proportioned to one another by measure instead of weight.

A little after the use of flint had been introduced, an improvement was made by an ingenious mechanic in the neighbourhood, Mr Alfager, in the potter’s wheel, by which its motion was greatly accelerated. This enabled the potters to form their ware not only with greater expedition and facility, but likewise with more neatness and precision, than they had done before.

By these means the manufacture

[41]

was so far improved , in the beginning of the present century, as to furnish various articles for tea and coffee equipages, and soon after for the dinner table also. Before the middle of the century these articles were manufactured in quantity, as well for exportation as home consumption. The salt glaze, however, the only one then in use for those purposes, is in its own nature so imperfect, and the potters, from an injudicious competition among themselves for cheapness, rather than for excellence, had been so inattentive to elegance of forms and neatness of workmanship that this ware began to be rejected from genteel tables, and supplanted by a white ware of finer forms and more beautiful glaze, which

[42]

about the year 1760, was imported in considerable quantities from France.

This inundation of foreign manufacture; so much superior to our own, must have had very bad effects upon the Potteries of this kingdom, if a new one, still more to the public taste, had not happily been soon after produced here. In 1763, Mr. Josiah Wedgwood, who had already introduced several improvements into this art, as well as with respect to the forms and colours of the wares, as the composition of which they were made, invented a species of earthen-ware for the table, of a firm and durable body, and covered with a rich and brilliant glaze, and bearing sudden

[43]

vicissitudes of cold and heat without injury: it was accompanied also with the advantage of being manufactured with ease and expedition, was sold cheap, and as it possessed, with the novelty of its appearance, every requisite quality for the purpose intended, it came quickly into general estimation and use. To this manufacture the Queen was pleased to give her name and patronage, commanding it to be called Queen’s Ware, and honouring the inventor by appointing him her Majesty’s potter.

This ware is composed of the whitest clays from Devonshire, Dorsetshire, and other places, mixed with a due portion of ground flint. The pieces are fired twice, and the glaze applied

[44]

after the first firing, in the same manner as on porcelain. The glaze is a vitreous composition of flint and other white earthy bodies, with an addition of white lead for the flux, analogous to common flint glass; so that when prepared in perfection, the ware may be considered as coated over with real flint glass. This compound being mixed with water to a proper consistence, the pieces, after the first firing, are separately dipt in it: being somewhat bibulous, they drink in a quantity of the mere water, and the glaze which was united with that portion of the water remains adherent, uniformly, all over their surface, so as to become, by the second firing a coat of perfect glass.

[45]

To the continued experimental researches of the same person, we owe the invention of several other species of earthen-ware and porcelain, adapted to various purposes of ornament and use. The principal are the six following:

1. A Terra cotta; resembling porphyry, granite, Egyptian pebble, and other beautiful stones of the siliceous or crystalline order.

2. Basaltes, or black ware; a black porcelain biscuit of nearly the same properties with the natural stone; striking fire with steel, receiving a high polish, serving as a touchstone for metals, resisting all the acids, and bearing, without injury, a strong fire,

[46]

stronger indeed than the basaltes itself.

3. White porcelain biscuit; of a smooth wax-like surface, of the same properties with the preceding, except in what depends upon colour.

4. Jasper; a white porcelain biscuit of exquisite beauty and delicacy, possessing the general properties of the basaltes, together with the singular one of receiving through its whole substance, from the admixture of metallic calces with the other materials, the same colours which those calces communicate to glass or enamels in fusion; a property which no other porcelain or earthen-ware body, of ancient or modern composition,

[47]

has been found to possess. This renders it peculiarly fit for making cameos, portraits, and all subjects in bas relief, as the ground may be of any particular colour, while the raised figures are of a pure white.

5. Bamboo; or cane-coloured biscuit porcelain; of the same nature as No 3.

6. A porcelain biscuit, remarkable for great hardness, little inferior to that of agate; this property, together with its resistance to the strongest acids and corrosives, and its impenetrability by every known liquid, adapts it for mortars and many different kinds of chemical vessels.

[48]

These six distinct species, with the queen’s ware already mentioned, expanded by the industry and ingenuity of the different manufacturers, into an infinity of forms for ornament and use, variously painted and embellished, constitute nearly the whole of the present fine English earthenware and porcelain, which are now become the source of a very expansive trade, and which, considered as an object of national art, industry, and commerce may be ranked amongst the most important manufacturies of the kingdom.

The evidence given by Mr. Wedgwood to the committee of Privy Council, and at the bars of the two houses of Parliament, when a commercial arrangement with Ireland was

[49]

in agitation, in 1785, will give some idea of the present extent of this manufacture, and of its value to our maritime and landed, as well as our commercial interests.

Though the manufacturing part alone, in the Potteries and their vicinity, gives bread to near thirty thousand people, including the wives and children of those who are employed in it, he looks upon this as a small object when compared with the many others which depend on it, namely: 1. The immense quantity of inland carriage it creates throughout the kingdom, both for its raw materials and finished goods: – 2. The great number of people employed in the

[50]

extensive collieries for its use: – 3. The still greater number employed in raising and preparing its raw materials, in several distant parts of England, from near the Land’s-end in Cornwall – one way along different parts of the coast to Falmouth, Teignmouth, Exeter, Poole, Gravesend, and the Norfolk coast – the other way, to Biddeford, Wales, and the Irish coast: – 4. The coasting vessels, which, after having been employed at the proper season in the Newfoundland fishery, carry these materials coast-wise to Liverpool and Hull, to the amount of more than 20,000 tons yearly, at times when they would otherwise be laid up idle in harbour: – 5. The further conveyance of them from those

[51]

ports by river and canal navigation to the Potteries situated in one of the most inland parts of the kingdom: and 6. The re-conveyance of the finished goods to the different ports of this island, where they are shipped for every foreign market that is open to the earthen-ware of England.

He observes further, that this manufacture is attended with some advantageous circumstances almost peculiar to itself, viz. that the value of the manufactured goods consists almost wholly in labour; that one ton of raw materials produces several tons of finished goods for shipping, the freight being then charged, not by

[52]

the weight, but by the bulk; that scarce a vessel leaves any of our ports without more or less of these cheap, bulky, and therefore valuable articles to this maritime country; and, above all, that not less than five parts in six, of the whole produce of the potteries, are exported to foreign markets.

Important as the Pottery may now appear, and rapid as its progression has been within the last thirty years, Mr. Wedgwood in his evidence to the House of Commons, declares himself strongly impressed with the idea, that the art is still but in its infancy compared with what it may arrive at if not interrupted in its growth.

[53]

In a history of Commerce lately published,* the editor, after quoting Mr. Wedgwood’s evidence, supposes that by this last expression he alludes to the introduction of excise laws in the Pottery, of which, it seems, there was some talk at that time; but adds, very justly that it would have been too impolitic a step to check to growing a manufacture by excise laws, more especially, when five-sixths of the duty collected must have been paid back again upon exportation of the goods, and an opening thereby made for fraud, which if we may judge from

*Appendix to the second edition of Anderson’s History of Commerce. Vol. iv p. 700

[54]

what has been practiced in some other articles, would have made the drawback amount to more than the original payment.

To the preceding general account of the manufacture, we shall add a more particular description of the process used in manufacturing the earthenware.

A piece of the prepared mixture of clay and ground flint, dried and tempered to a proper consistence, is taken to be formed into any required shape and fashion, by a man who sits over a machine called a wheel, on the going round of which he continues forming the ware. This branch is

[55]

called throwing, and as water is required to prevent the clay sticking to the hand, it is necessary to place it for a short time in a warm situation. It then undergoes the operation of being turned and made much smoother than it was before by a person called a turner; when it is ready for the handle and spout to be joined to, by the branch called handling.- Dishes, plates, tureens, and many other articles are made from moulds of ground plaister, and when finished, the whole are placed carefully (being then in a much more brittle state than when fired) in saggers, which in shape and form pretty much resemble a lady’s band-box without its cover, but much thicker, and are made

[56]

from the marl or clay of this neighbourhood. The larger ovens or kilns are placed full of saggers so filled with ware; and after a fire which consumes from 12 to 15 tons of coal; when the oven is become cool again, the saggers are taken out, and their contents removed, often exceeding in number 30,000 various pieces; but this depends upon the general sizes of the ware. In this state the ware is called biscuit, and the body of it has much the appearance of a new tobacco pipe, not having the least gloss upon it. It is then immersed or dipped into a fluid generally consisting of white lead, ground flint, and a stone from Cornwall burnt and ground, all mixed together, and

[57]

as much water put to it as reduces it to the thickness of cream, which it resembles. Each piece of ware being separately immersed or dipped into this fluid, so much of it adheres all over the piece, that when put into other saggers, and exposed to another operation of fire, performed in the glossing kiln or oven, the ware becomes finished by acquiring its glossy covering, which is given it by the vitrification of the above ingredients. Enamelled ware undergoes a third fire after its being painted, in order to bind the colour on.

A single piece of ware, such as a common enamelled tea-pot, a mug, jug, &c. passes through at least four-

[58]

teen different hands before it is finished, viz.

The slipmaker, who makes the clay.

The temperer, or beater of the clay.

The thrower, who forms the ware.

The ball-maker and carrier.

The attender upon the drying of it.

The turner, who does away its roughness.

The spout-maker.

[59]

The second, or gloss fireman.

The dresser, or sorter in the warehouse.

The enameller or painter.

The mussle, or enamel fireman.

Several more are required to the completion of such piece of ware, but are in inferior capacities; such as turners of the wheel, turners of the lathe, &c. &c.

We cannot more properly close this account of the Staffordshire Potteries, than with a biographical record of the person to whom they have been so much indebted,

[60]

extracted from the Gentleman’s Magazine, for January 1795, the period of his much lamented death.

“Died at Etruria in Staffordshire, aged 64, JOSIAH WEDGWOOD Esq. F.R. and A.S.S. to whose indefatigable labours is owing the establishment of a manufacture that has opened a new scene of extensive commerce, before unknown to this or any other country,- It is unnecessary to say that this alludes to the Pottery of Staffordshire, which, by the united efforts of Mr. WEDGWOOD, and his late partner, Mr. BENTLEY, has been carried out to a degree of perfection, both in the line of

[61]

utility and ornament, that leaves all works, ancient or modern, far behind.

Mr. WEDGWOOD was the younger son of a potter, but derived little or no property from his father, whose possessions consisted chiefly of a small entailed estate, which descended to the eldest son. He was the maker of his own fortune, and his country has benefited in a proportion not to be calculated. His many discoveries of new species of earthen-wares and porcelains; his studied forms and chaste style of decoration, and the correctness and judgement with which all his works were executed under his own eye,

[62]

and by artists, for the most part of his forming, have turned the current in this branch of commerce; for, before his time, England imported the finer earthen-wares; but for more than twenty years past, she has exported them to a very great annual amount, the whole of which is drawn from the earth, and from the industry of the inhabitants, while the national taste has been improved, and its reputation raised in foreign countries. His inventions have prodigiously increased the number of persons employed in the Potteries, and in the traffic and transport of their materials from distant parts of the kingdom; and this class of manufacturers is also indebted to him for

[63]

much mechanical contrivance and arrangement in their operations; his private manufactory having had for thirty years and upwards, all the efficacy of a public work of experiment. Neither was he unknown in the walks of Philosophy: his communications to the Royal Society, shew a mind enlightened by science and contributed to procure him the esteem of scientific men at home and throughout Europe. His invention of a Thermometer for measuring the higher degrees of heat, employed in the various arts, is of the highest importance to their promotion, and will add celebrity to his name.- At an early period of his life,

[64]

seeing the impossibility of extending considerably the manufactury he was engaged in on the spot which gave him birth, without the advantages of inland navigation, he was the proposer of the Grand Trunk canal, and the chief agent in obtaining the Act of Parliament for making it, against the prejudices of the landed interest, which at times stood very high, and but just before had been with great difficulty overcome in another quarter, by all the powerful influence of a noble Duke, whose canal was at that time but lately finished. Having acquired a large fortune, his purse was always open to the calls of charity, and to the support of every institution for the

[65]

public good. To his relations, friends and neighbours, he was endeared by his many private virtues; and his loss will be deeply and long deplored by all who had the pleasure of knowing him intimately, and by the numerous objects to whom his benevolence was extended; and he will be regretted by his country, as the able and zealous supporter of her commerce, and the steady patron of every valuable interest of society.

We shall add that the great concerns of the late Mr. Wedgwood, are now under the joint management of Messrs. Josiah Wedgwood, and Thos. Byerley.

A Map of the Potteries, Staffordshire