Types of Glass

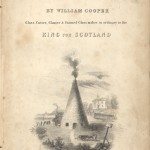

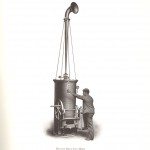

Image: Glass Pots in which the ingredients used in glassmaking were fired. These were made from Stourbridge clay in controlled conditions to ensure that they were free of air bubbles and dried very slowly. The Useful Arts and Manufacturers of Great Britain of Great Britain, Vol. 1 (London, SPCK, 1846?)

Image from: Science, Technology and Management, Birmingham Central Library

The three types of glass that Chances produced were crown, plate or sheet glass and flint glass. The bases for all three were silica and a metallic oxide. The proportions of ingredients varied according to the kind of glass made and the individual practice of each glass producer, who guarded their recipes carefully. Generally the ingredients and proportions were as follows:

- Crown glass: 63 % white sand, 7 % chalk, 30 % soda

- Plate glass: 55 % white sand, 35 % soda, 8 % soda, 2% lime

- Flint glass: 52% white sea sand, 14% potash, 34% oxide of lead

The glass was produced in cone-shaped glass houses with wide open-top chimneys. Inside there was a central furnace surrounded by six to eight pots made of Stourbridge clay. Raw ingredients were placed into these pots and heated and mixed until the “metal” fused into a soft mass. The exhibition The Smethwick Glass Works of Chance Brothers, West Midlands (Theme: Industry and Innovation) provides a further insight into manufacturing processes.

« Previous in this sectionNext in this section »Continue browsing this section

The Infinite Uses of Glass: Chance Brothers, Glassmakers of Smethwick

The Infinite Uses of Glass: Chance Brothers, Glassmakers of Smethwick

Chance Brothers and Company

Chance Brothers and Company

The Arrival of Expert Workers

The Arrival of Expert Workers

The Chemical Works

The Chemical Works

Types of Glass

Types of Glass

Crown Glass

Crown Glass

Plate or Sheet Glass

Plate or Sheet Glass

Flint Glass

Flint Glass

New Technology

New Technology

Glazing the Crystal Palace

Glazing the Crystal Palace

Glazing the Crystal Palace

Glazing the Crystal Palace

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Lighthouse Production

Company Philanthropic Activity

Company Philanthropic Activity

Relations between Workers and the Company

Relations between Workers and the Company

French and Belgian Workers

French and Belgian Workers

Description of the Glassworks

Description of the Glassworks

Description of the Glassworks

Description of the Glassworks